We provide mechanical design services for ground support equipment for aeroplanes. We tailor our services to meet the unique demands of each aircraft. Additionally, our team brainstormed different ideas and provided the client with multiple design solutions based on their requirements. We guided the client to choose the best design option for their needs. Then, we created a 3D design model according to their specifications and shared the CAD model with the client before fabrication.

Simply put, skid testing involves simulating scenarios where a vehicle’s wheels lose traction, causing it to slide or skid. By recreating these conditions in a controlled environment, engineers can evaluate how well anti-skid systems and other safety features perform.

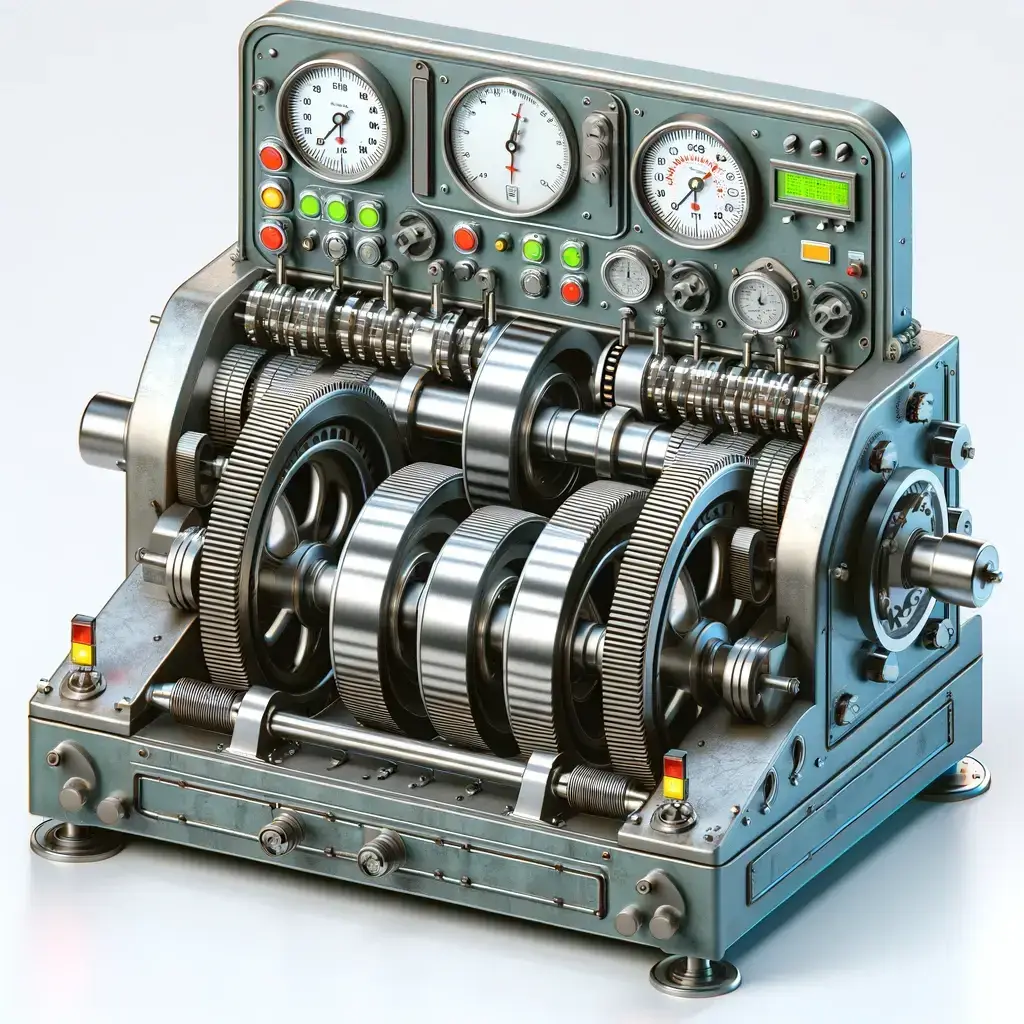

Furthermore, we designed the product while considering the availability of required items in the local market. We utilized optimal machining operations to minimize costs. As a result, we developed an easily manufacturable design that meets all client requirements. The equipment had a robust structure strengthened by mild steel pipes, ensuring resilience under extreme conditions. The equipment has a motor-driven roller with sensors in place.

In this regard, successful mechanical design services lie in the ability to withstand various forces and movements without compromising safety or performance. Furthermore, skid testing movement offers a comprehensive approach to evaluating and optimizing the dynamic behavior of your designs, ensuring they meet the highest standards of quality and durability.

Moreover, the motor drives the roller at a constant speed, which in turn rotates the aircraft’s wheel. The sensors will give real-time indications for skid occurrence by measuring the rpm difference between the wheel and the roller. This state-of-the-art mechanism can easily test the anti-skid system of the aircraft efficiently. The equipment’s outer body is crafted from mild steel plates, designed to withstand rigorous aviation testing. Our thorough structural analysis ensures equipment durability under extreme loads, ensuring prolonged operation.