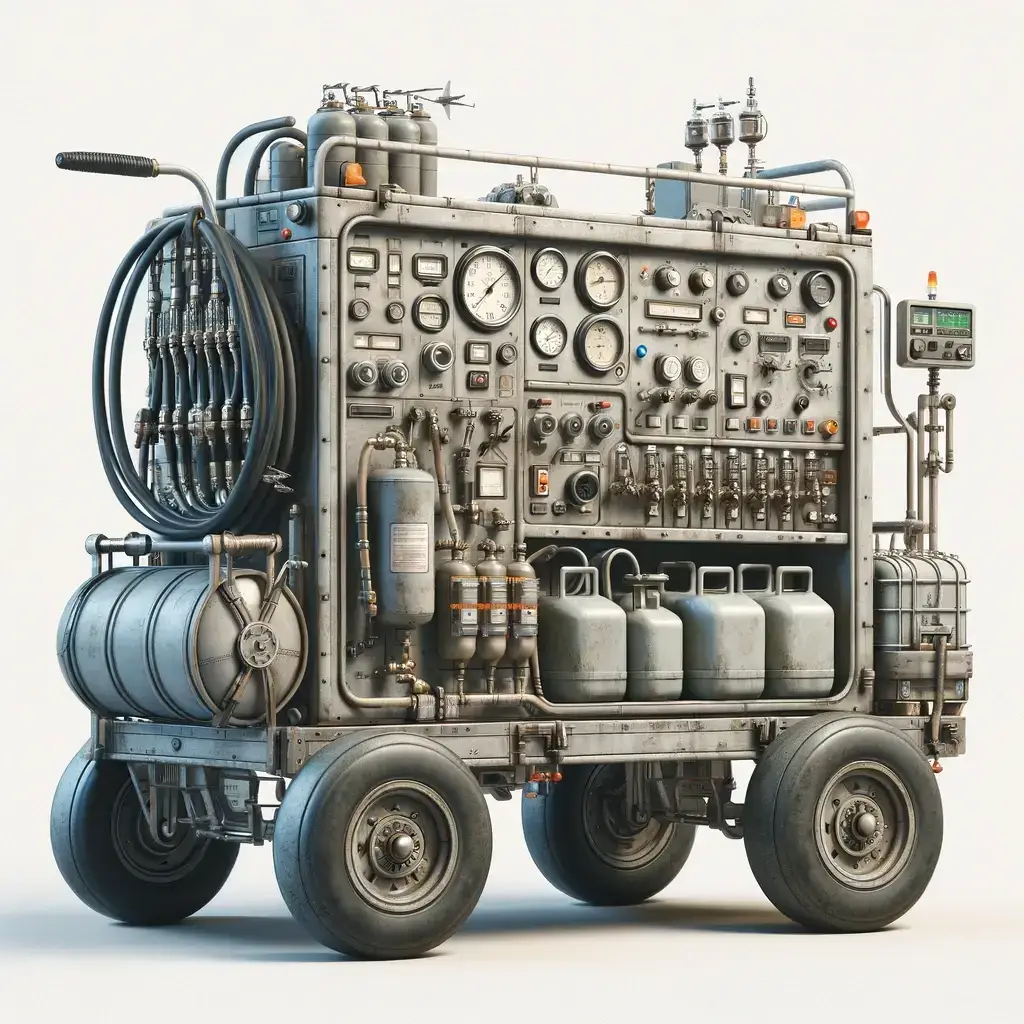

A hydraulic refiller was designed to refill oil and lubricants for different machineries and equipment. Careful consideration was given to the requirements of the client, keeping the client in loop and discussing the results in every stage of the design process. Based on the requirements of the client, multiple design solutions were provided to the client after our team brainstormed different ideas. Then the client was guided to choose the best possible design according to their requirements. A 3D model of the design was made according to the requirements of the client, the CAD model was shared with the client prior to its fabrication. The design was created by considering that the required items for the design were available in the local market, optimal and available machining operations were used to minimize the cost. Therefore, an easily manufacturable design was developed, which satisfies all the requirements of the client. The structural integrity of the product was strengthened by mild steel pipes and sheets. The gauge of both the steel pipes and sheets was chosen as 16 to ensure durability, resilience, and reliability. This can be proven from the fact that it is designed to be used for diverse applications such as aircrafts, machineries, automobiles etc. The oil is stored in a tank. The tank is made of 316 food grade stainless steel, which ensures the safety and quality in storing the oils to be filled. The design incorporates a muti-stage filtration system, first the oil passes through a normal filter when it is filled into the tank, then it passes through 10 micron filter and a 3 micron filter when it is being filled into the required vessel. This ensures the purity of the oil is in exact accordance with the industrial requirements. Different values are installed in the system to allow precise control over the oil transfer process while gauges are used to monitor oil level.